Enhancing Fluid Transfer Efficiency: The Advantages of High Flow Quick Couplers

High flow quick couplers offer several advantages for enhancing fluid transfer efficiency in various applications. These couplers are specifically designed to handle high flow rates, making them ideal for industries where rapid fluid transfer is crucial. Here are some of the advantages of using high flow quick couplers:

Increased Flow Rates: High flow quick couplers are designed to allow fluid to pass through at a much higher rate compared to standard couplers. This feature significantly reduces the time required for fluid transfer, leading to improved productivity and efficiency.

Faster Equipment Setup and Changeovers: In industries where quick equipment setup and frequent changeovers are common, high flow quick couplers can save valuable time. Their fast connection and disconnection capabilities enable swift changes between different fluid lines or equipment, reducing downtime and enhancing operational efficiency.

Minimized Pressure Drops: Standard couplers often cause pressure drops due to their restrictive flow paths. High flow quick couplers, on the other hand, are engineered to minimize pressure losses during fluid transfer, ensuring that the fluid maintains its intended pressure and flow characteristics.

Reduced Energy Consumption: By minimizing pressure drops and facilitating faster fluid transfer, high flow quick couplers can help reduce energy consumption. This is particularly beneficial for systems that rely on pumps or other energy-intensive components to move fluids.

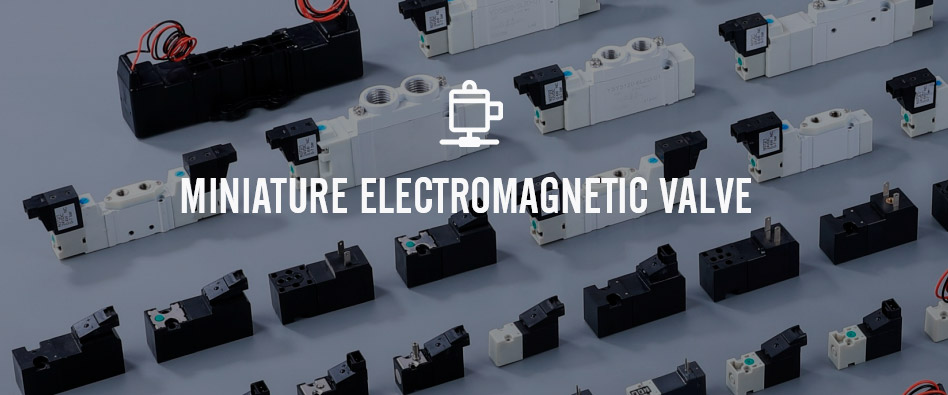

Compatibility and Versatility: High flow quick couplers are available in various sizes and configurations to accommodate different types of fluids and applications. They are compatible with a wide range of fluids, including liquids and gases, making them suitable for diverse industrial processes.

Improved Safety: The quick connection and disconnection mechanisms of high flow couplers enable operators to handle fluid transfer tasks more efficiently and safely. Reduced manual handling and faster connection times can help minimize the risk of spills, leaks, and accidents.

Enhanced Cleanliness: Some high flow quick couplers are designed with features that prevent fluid spillage during the connection and disconnection process. This not only improves safety but also helps maintain a cleaner working environment.

Durability and Longevity: High flow quick couplers are typically built to withstand high flow rates, pressure, and demanding industrial conditions. They are constructed from robust materials, ensuring long-lasting performance and reducing the need for frequent replacements.

Cost-Effective Solutions: Though high flow quick couplers may have a higher upfront cost compared to standard couplers, their advantages in terms of efficiency, productivity, and reduced downtime can lead to long-term cost savings for industries that rely heavily on fluid transfer processes.

In conclusion, high flow quick couplers offer numerous advantages for enhancing fluid transfer efficiency in industrial applications. Their ability to handle high flow rates, reduce pressure drops, and improve safety and cleanliness make them valuable tools for industries seeking to optimize their fluid transfer operations.

English

English 简体中文

简体中文