A metal connector series refers to a collection of connectors that are made of metal materials such as steel, aluminum, brass and copper, etc. They are designed to connect and disconnect different types of electrical or mechanical systems. Metal connectors are known for their high strength, durability, and resistance to corrosion, heat, and impact. They are often used in harsh environments and high-stress applications where reliability and performance are crucial.

Some examples of different metal connector series include:

Electrical connectors: which are used to connect electrical systems and devices such as wires, circuit boards, and power supplies

Mechanical connectors: which are used to connect mechanical systems such as pipes, hoses, and structural elements

RF connectors: which are used to connect radio frequency devices and cables in high-power applications

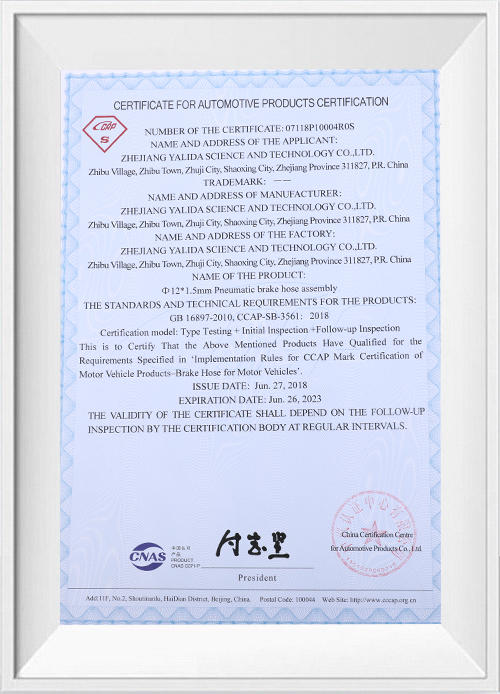

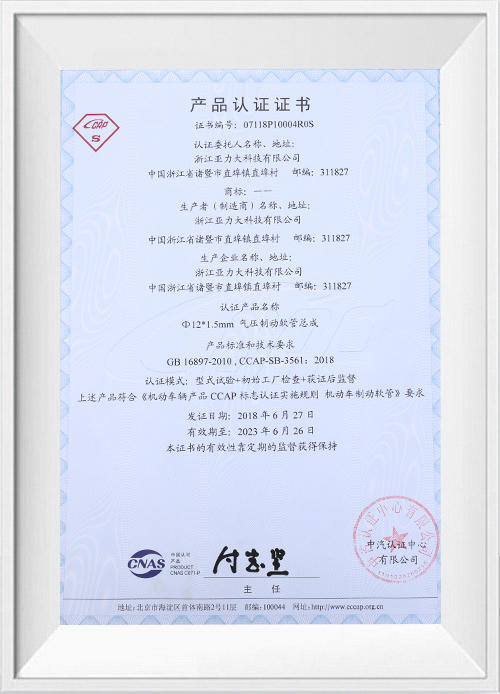

Automotive connectors: which are used to connect electrical systems in vehicles, such as lighting, audio, and power systems

Industrial connectors: which are used in a wide range of industrial applications, such as manufacturing, construction, and oil & gas industry

Aerospace connectors: which are used in aerospace and defense applications, such as aircraft and spacecraft systems

English

English 简体中文

简体中文